Cookies are used to make the most of our website. By logging in to this site you are deemed to accept the use of cookies. To learn more about cookies and our policy, please click on the link below.

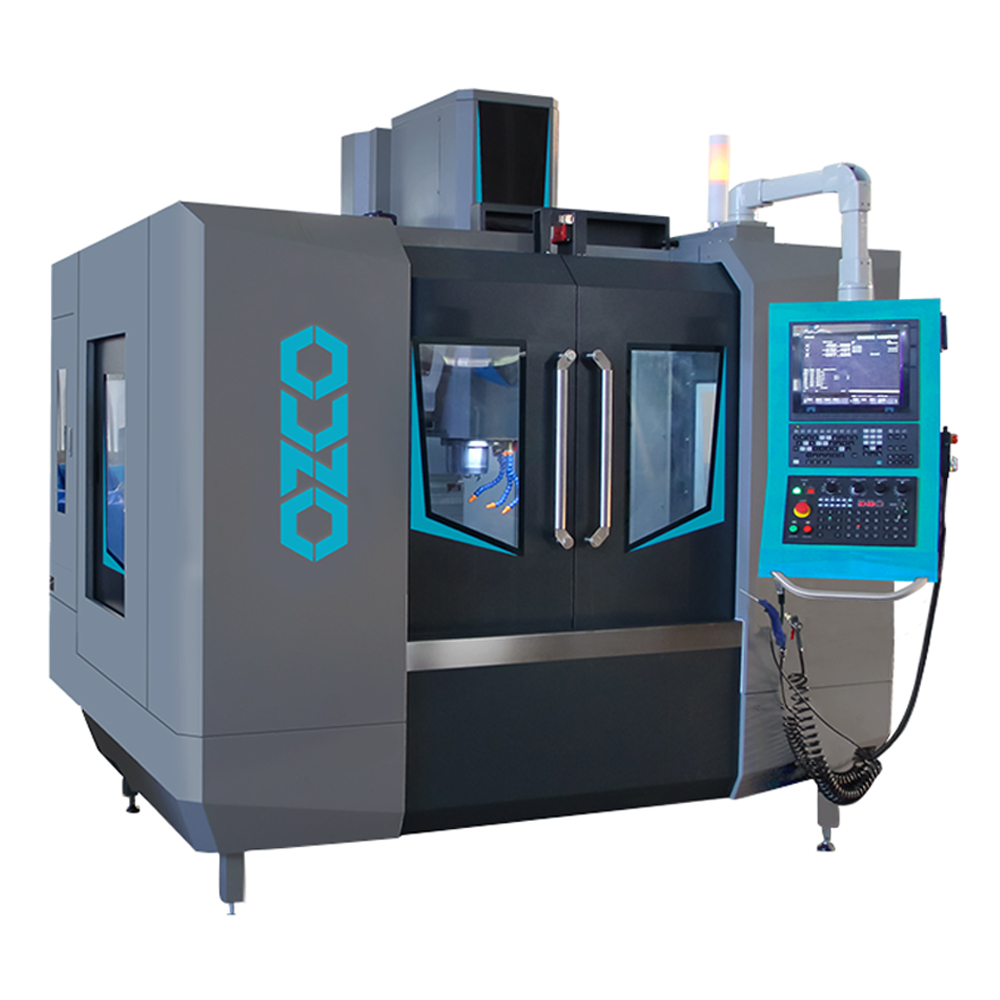

VM6 CNC Vertical Machining Center

- Technical Detail

- Description

- Involvement of Shipment

- Optional Accessories

| VM6 CNC Vertical Machining Center | |

|---|---|

| Main Motor Power | 5.5/7.5 kW |

| Table Size | 800x500 mm |

| T-slot Size | 5/18/90 mm mm |

| Max. Table Capacity | 400 kg kg |

| X,Y,Z Travel | 600,500,500 mm |

| Spindle-Table Distance | 120-620 mm |

| Spindle-Column Distance | 573 mm mm |

| Spindle Speed | 8,000 rpm (Belt Type) |

| Spindle Taper | BT40 |

| Spindle Diameter | 120 mm |

| X,Y,Z Rapid Feed Speed | 36/36/30 mm |

| X,Y,Z Motor Power | 2/2/3 kW |

| Cutting Feet Speed | 1-12000 mm/dak |

| Magazine Type/Capacity | 24 İstasyonlu Kol Tipi ATC |

| Max Tool Diameter | 80/150 mm mm |

| Tool-to-Tool Change Time | 1,55 sn |

| Control Unit | Mitsubishi M80A - Opsiyonel: Fanuc,Syntec |

| Driver and Encoder | Mitsubishi - Fanuc,Syntec |

| Main Motor Torque Power | 23,6/52,5 Nm |

| X,Y,Z Guideway Type | Masuralı Lineer Kızak |

| X,Y,Z Guideway | 35/35/35 mm |

| X,Y,Z Leadscrew Diameter | 32/32/32 mm |

| Positioning Accucary | 0.008 mm |

| Repeatabilty Accucary | +/-0.025 mm |

| Required Total Power | 21,3 kW/25 kVA |

| Machine Dimensions | 3450x2150x2450 mm |

| Net Weight | 4000 kg |

Hardware

•High-precision ball screws (Taiwan, HWIN)

•Linear roller guides with high rigidity and dynamic/static load capacity (Japan, THK)

•Specially designed, robust bearing group (Japan, NSK)

•High-efficiency and precision spindle (Taiwan, ROYAL)

•Reliable, high-quality electrical system (France, SCHNEIDER)

•Long-lasting central lubrication system (Japan)

•Low-vibration, wear-resistant, and precise tool magazine (Taiwan, POJU)

•All axis motors, drivers, encoders, and control units from MITSUBISHI or FANUC

•Ultra-durable, high-sealing cabin with stainless steel components for liquid contact areas, ergonomic workspace design with lighting and interior washing systems (Ozco patented design)

•High-strength, vibration-damping, rigid cast iron body (aged for 6+ months)

•3-axis linear roller guides

•Telescopic axis covers for all 3 axes

•Spindle/coolant system

•Air and coolant gun

•Rigid guide pull-out

•M30 automatic shutdown system

•Full mold package

•Electrical cabinet cooling system

•Leveling and balance pads

•Cabinet interior lighting

•3-color warning lamp

•Central lubrication system

•RS232 data transfer port

•P05 10,000-corner soft rotation function

•2x4 bar cabinet interior washing system

•MPG (Manual Pulse Generator)

•Fully enclosed cabin

•Chip conveyor (pallet-type for Direct Drive models)

•Ready 4th axis electrical system for CNC rotary table

•380V/50 Hz transformer

•CE compliance

•Fanuc 0i-MF Plus control unit, Syntec M22A

•Through-spindle coolant (CTS)

•255mm rotary table, TJR

•Rotary table tailstock

•Rotary table mirrored tailstock