Cookies are used to make the most of our website. By logging in to this site you are deemed to accept the use of cookies. To learn more about cookies and our policy, please click on the link below.

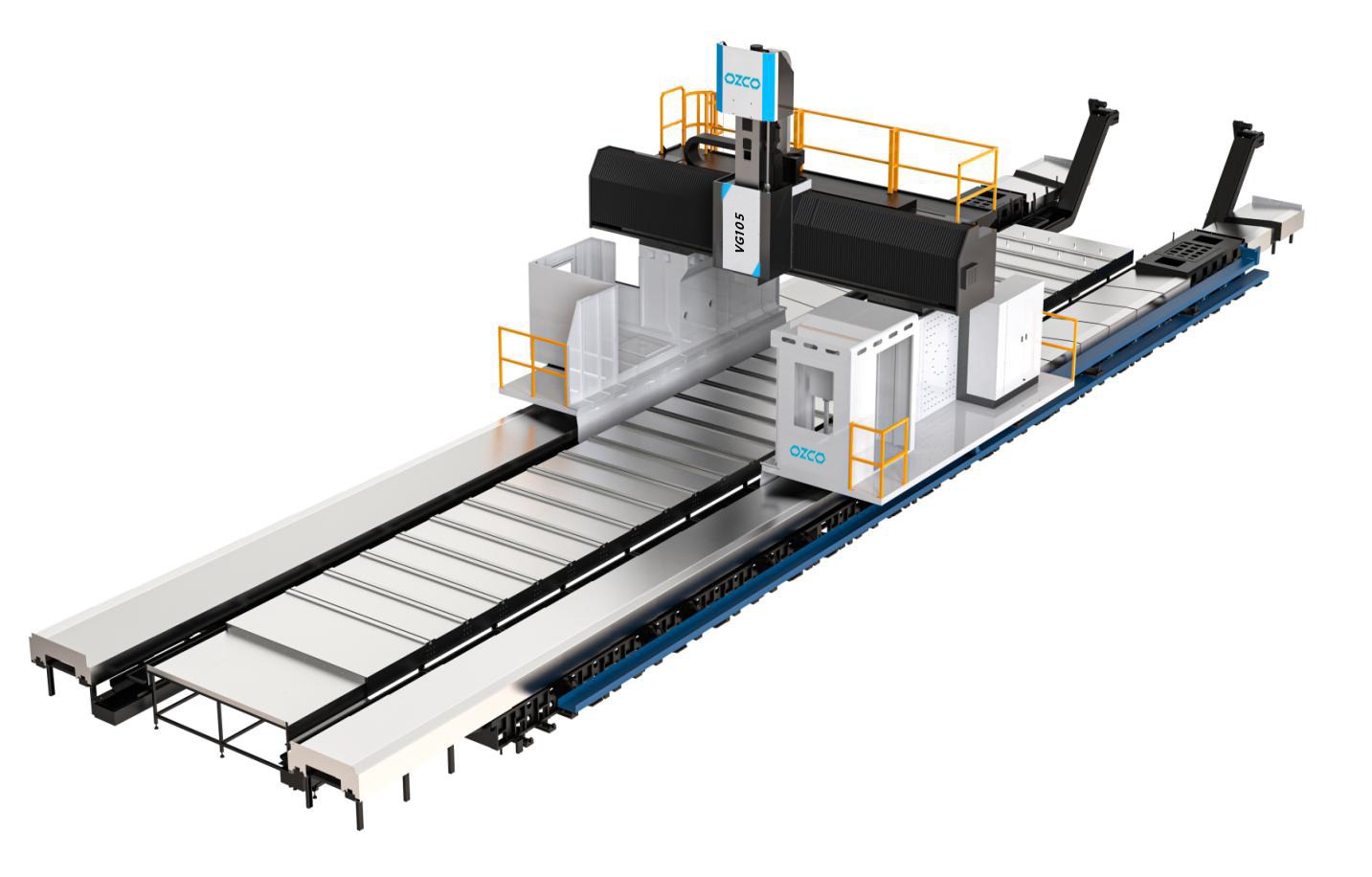

VG105 CNC Double Column Vertical Machining Center

- Technical Detail

- Description

- Involvement of Shipment

- Optional Accessories

| VG105 CNC Double Column Vertical Machining Center | |

|---|---|

| Spindle Motor Power | 30/37 kW |

| Table Size | 10000/12000/14000/16000/20000/24000 |

| T-slot Size | 36x260 mm |

| Max. Table Capacity | 15000 kg |

| X Axis Travel | 10200/12200/14200/16200/20200/24200 mm |

| Y Axis Travel | 5200 mm |

| Z Axis Travel | 1250 mm |

| Spindle Speed | 5200 rpm |

| Spindle Taper | BT50 |

| Max Tool Diameter | Φ250 mm |

| X,Y,Z Rapid Feed Speed | 10/10/10 |

| Magazine Capacity | 30 (opt. 40 or 60) |

| Max Tool Diameter | Ø125/350 mm |

| Control Unit | FANUC 0I-MF 1(Opt. Siemens 828D) |

| Driver and Encoder | FANUC 0I-MF 1 |

| Main Motor Torque Power | 1338Nm |

| Repeatability Positioning Accuracy X/Y/Z | X: 10m: 0.055/0.034 12m : 0.06/0.038 14m: 0.065/0.042, Y:0.03/0.02 mm, Z: 0.02/0.013 mm |

| Machine Size | 16000x8000x4000 mm |

| Weight | 135.000 |

•Fanuc 0i MF(1) controller with USB Port, CF card

•Square ram spindle

•Lubrication

•X-axis configuration with Heidenhain optical scale

•X1 / X2 double motor gap elimination

•Spindle speed change adopts self-made gearbox

•Spindle Oil cooler

•Big section cross beam, the guide amounted on the top and front position to realize the high rigidity and avoid the deformation.

•Electric cabinet air conditioning

•Equipped with the ladder and guard rail for convenient and safe operation

•Provide the positive air pressure to prevent contaminents influnce the spindle.

•Water gun, air gun Chain-type chip conveyor

•Taiwan Deta 30 disc type tool magazine

•Center water outlet 2MP

•Center water outlet 7MP

•Renishaw TS27R

•Renishaw OMP 60

•Manual Right-angular Milling Head

•Automatic 90° milling head(index 5°) or similar Automatic head changer including

•Optional automatic Milling Head (3+2 axis milling head)

•Automatic head changer including

•40 Chain type tool magazine